Quick Navigation:

| | |

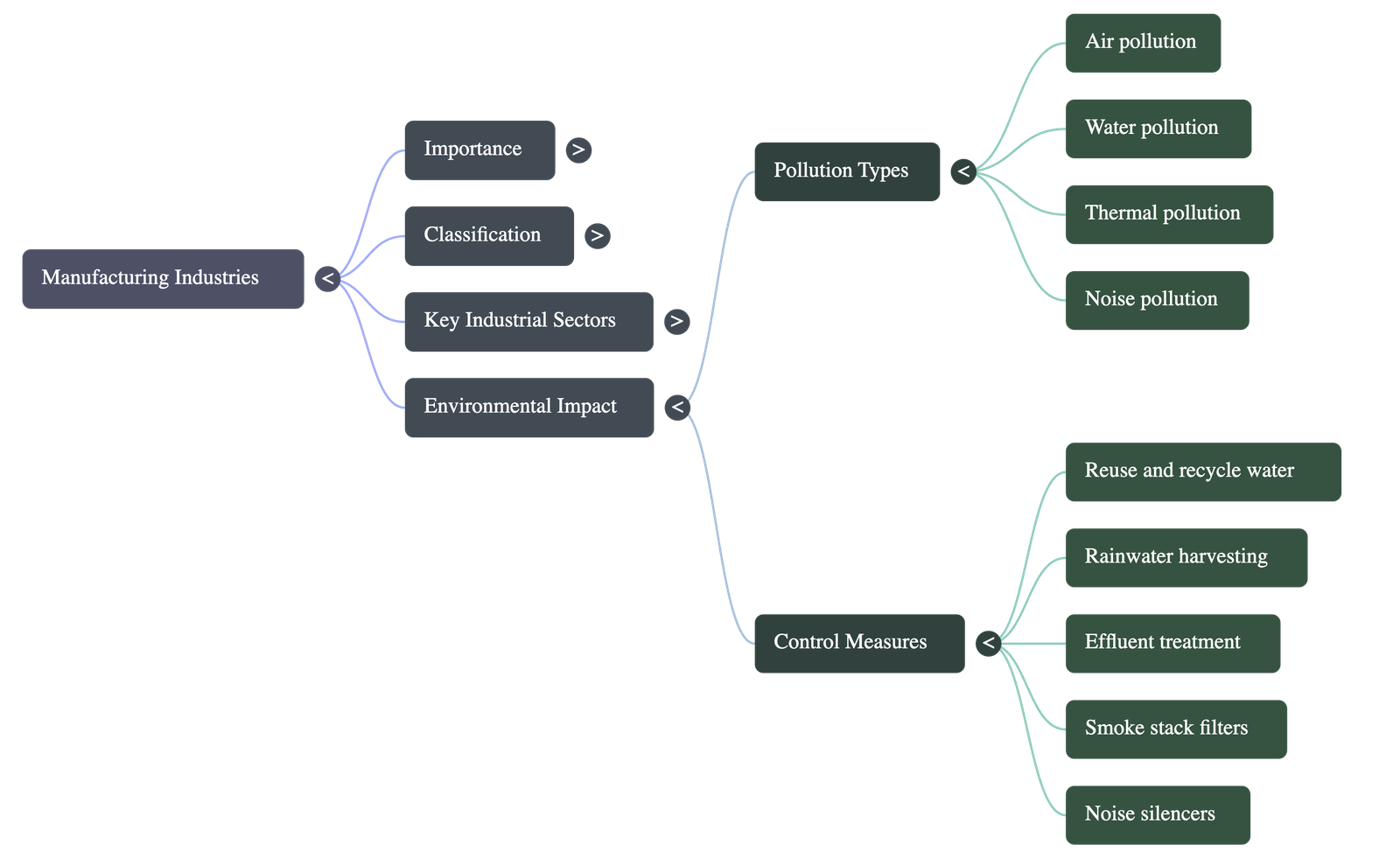

Manufacturing Industries

Introduction to Manufacturing

- Definition: Manufacturing is the production of goods in large quantities after processing raw materials into more valuable products.

- Sector: It falls under the secondary sector.

- Economic Strength: The economic strength of a country is measured by the development of its manufacturing industries.

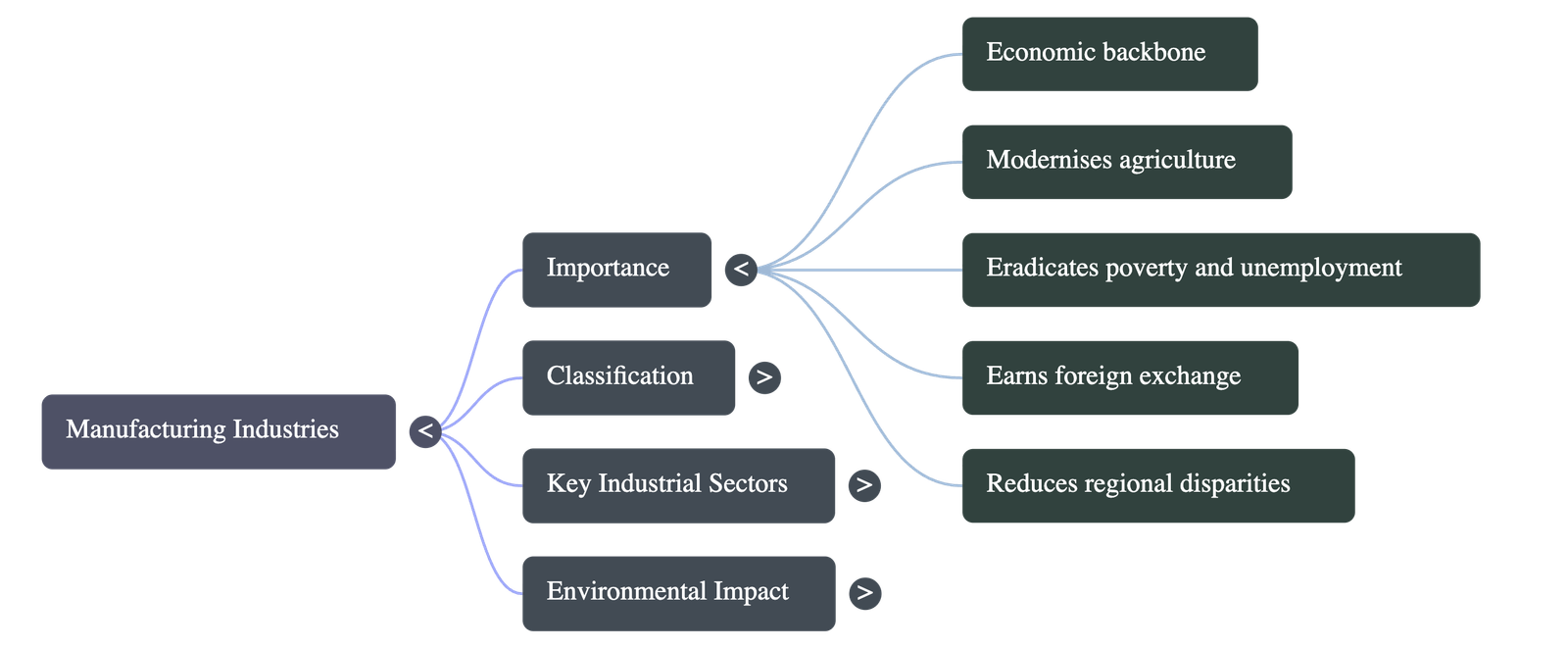

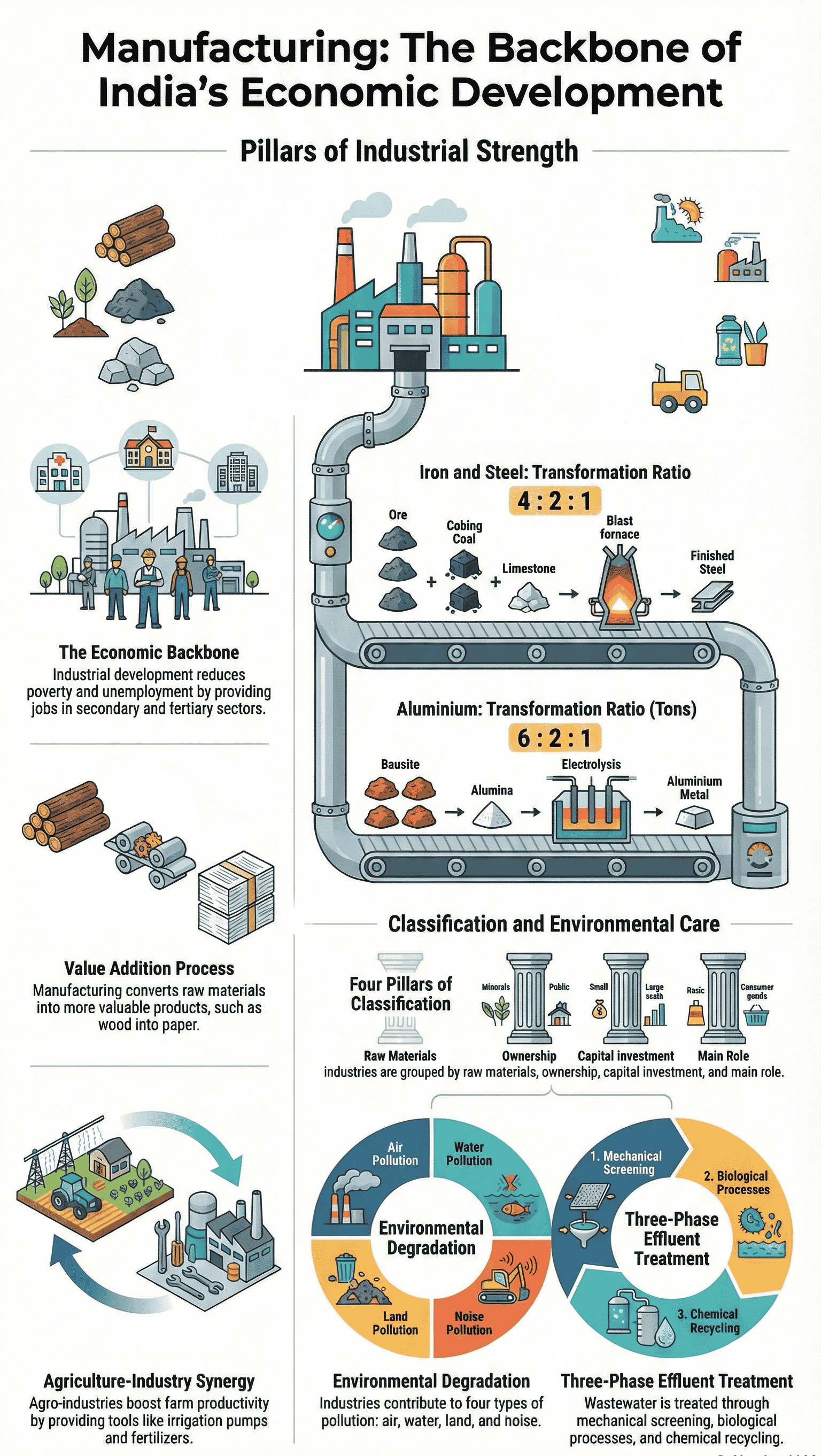

Importance of Manufacturing

- Modernizing Agriculture: Helps in modernizing agriculture, which is the backbone of the economy.

- Job Creation: Reduces dependence on agricultural income by providing jobs in secondary and tertiary sectors.

- Poverty Eradication: Industrial development is a precondition for eradicating unemployment and poverty. It aims to bring down regional disparities by establishing industries in backward areas.

- Foreign Exchange: Export of manufactured goods expands trade and brings in foreign exchange.

- Prosperity: Countries that transform raw materials into high-value finished goods are prosperous.

- Agriculture and Industry Link: They are not exclusive but move hand in hand. Agro-industries boost agriculture by raising productivity, and agriculture provides raw materials to industries.

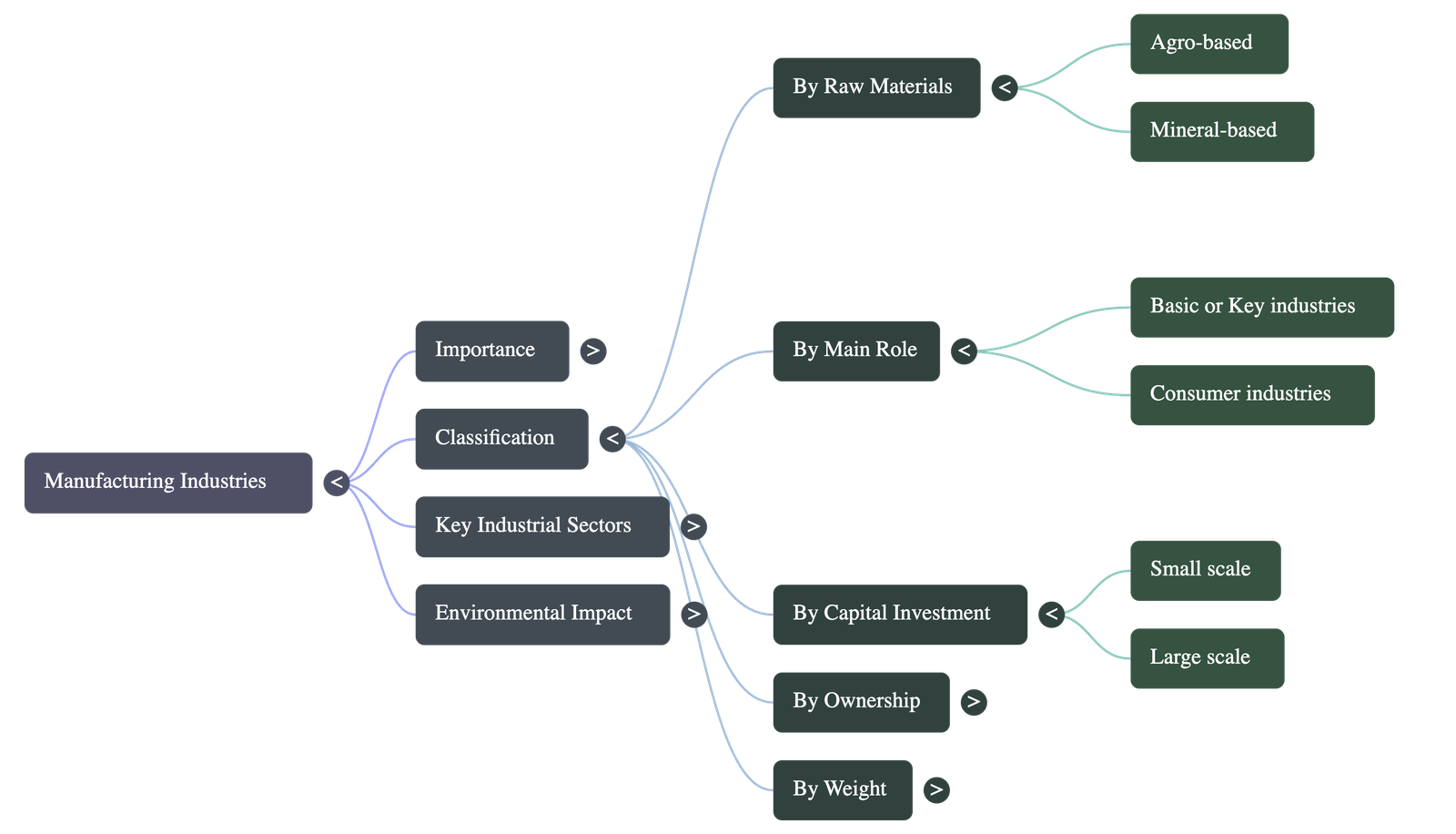

Classification of Industries

1. On the basis of Raw Materials

- Agro-based: Cotton, woollen, jute, silk textile, rubber, sugar, tea, coffee, edible oil.

- Mineral-based: Iron and steel, cement, aluminium, machine tools, petrochemicals.

2. On the basis of Main Role

- Basic/Key Industries: Supply their products as raw materials to manufacture other goods (e.g., iron and steel, copper smelting).

- Consumer Industries: Produce goods for direct use by consumers (e.g., sugar, toothpaste, paper, fans).

3. On the basis of Capital Investment

- Small Scale Industry: Defined by the maximum investment allowed on the assets of a unit (currently rupees one crore).

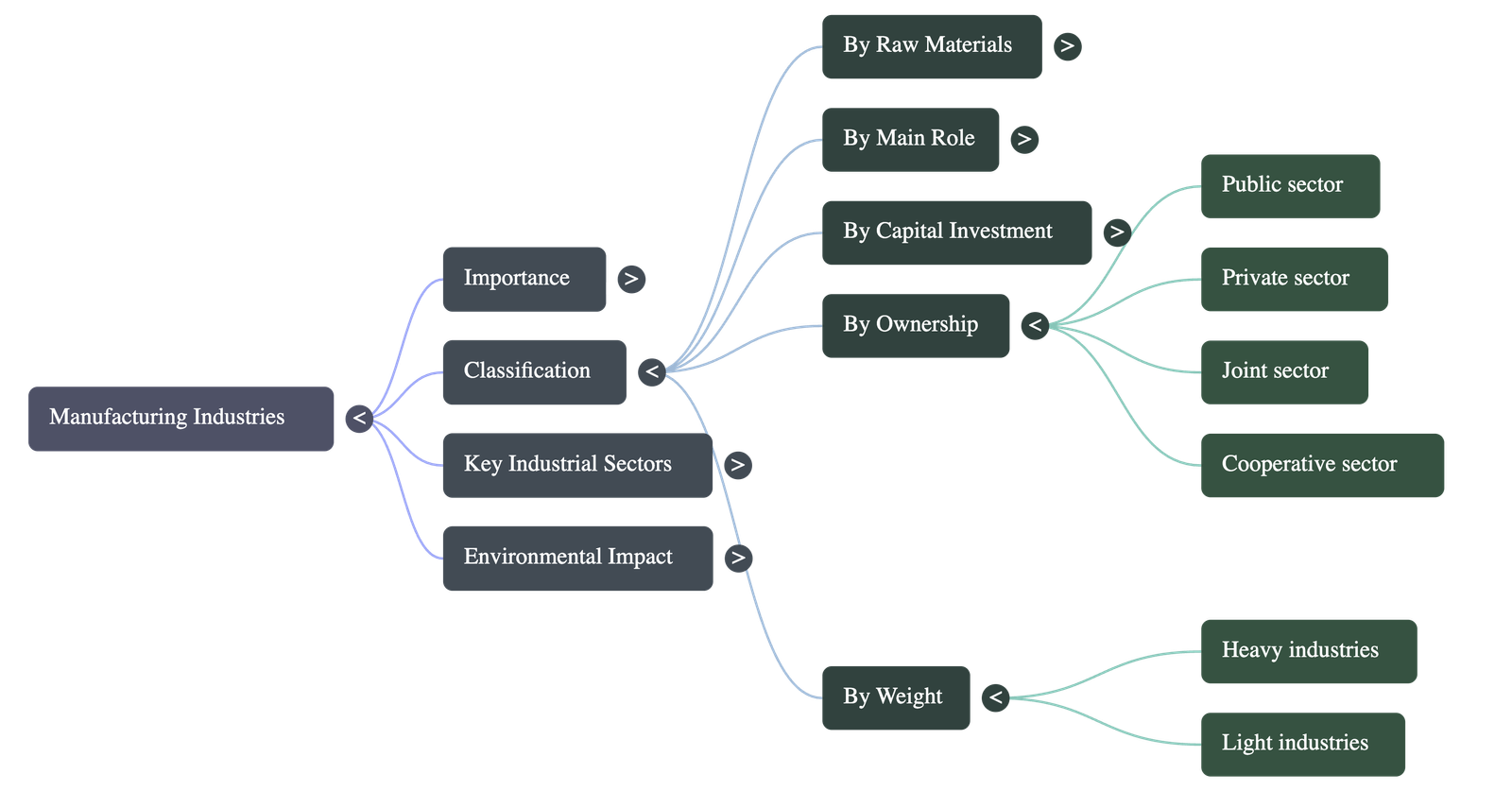

4. On the basis of Ownership

- Public Sector: Owned and operated by government agencies (e.g., BHEL, SAIL).

- Private Sector: Owned and operated by individuals or groups (e.g., TISCO, Bajaj Auto Ltd.).

- Joint Sector: Jointly run by the state and individuals (e.g., Oil India Ltd).

- Cooperative Sector: Owned and operated by producers/suppliers of raw materials or workers. They pool resources and share profits (e.g., Sugar industry in Maharashtra, Coir industry in Kerala).

5. On the basis of Bulk and Weight

- Heavy Industries: e.g., Iron and steel.

- Light Industries: Use light raw materials and produce light goods (e.g., electrical goods).

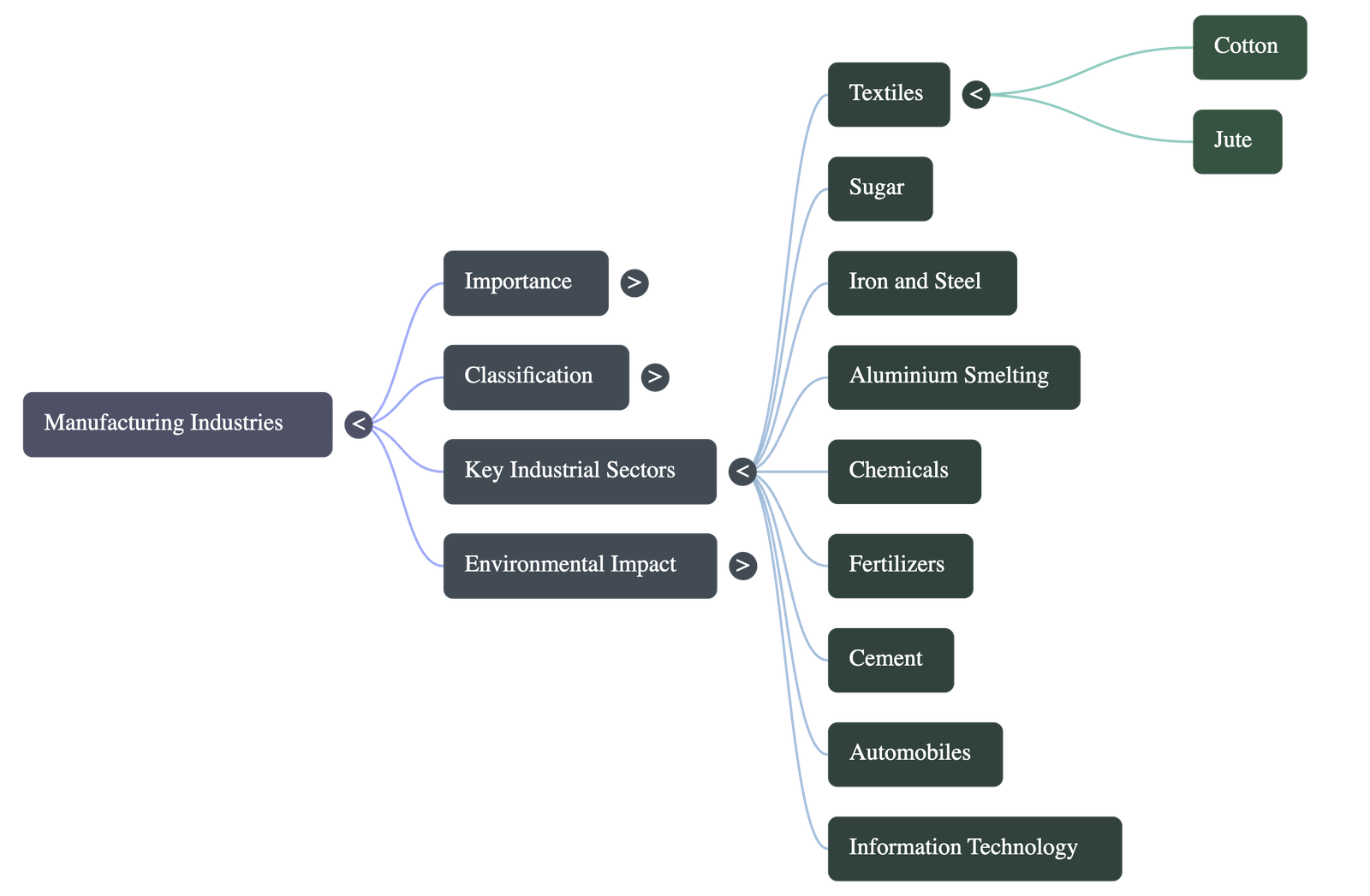

Major Agro-Based Industries

Textile Industry

- Unique position in the Indian economy.

- Contributes significantly to industrial production, employment, and foreign exchange.

- Self-reliant and complete in the value chain (from raw material to value-added products).

Cotton Textiles

- Historically produced with hand spinning and handloom weaving.

- Location Factors: Availability of raw cotton, market, transport, moist climate, and cheap labor. Originally concentrated in Maharashtra and Gujarat.

- Current Status: Spinning is centralized (Maharashtra, Gujarat, TN), but weaving is highly decentralized to incorporate traditional skills.

- Challenges: Erratic power supply, outdated machinery, low labor output, and stiff competition from synthetic fiber.

Jute Textiles

- India is the largest producer of raw jute and the second-largest exporter of jute goods.

- Location: Most mills are in West Bengal along the Hugli river.

- Factors for Location: Proximity to jute producing areas, inexpensive water transport, abundant water for processing, and cheap labor from nearby states.

Sugar Industry

- India is the second-largest producer of sugar in the world and first in gur and khandsari.

- Nature: Seasonal industry, ideally suited to the cooperative sector.

- Shifting Trends: Mills are shifting to southern and western states (especially Maharashtra) due to higher sucrose content in cane, cooler climate ensuring longer crushing seasons, and successful cooperatives.

Major Mineral-Based Industries

Iron and Steel Industry

- Basic Industry: All other industries depend on it for machinery.

- Heavy Industry: Raw materials and finished goods are bulky.

- Raw Materials: Iron ore, coking coal, and limestone are required in a ratio of approximately 4:2:1. Manganese is used to harden steel.

- Location: Maximum concentration in the Chhotanagpur plateau region due to low cost of iron ore, high-grade raw materials, and cheap labor.

Aluminium Smelting

- Second most important metallurgical industry in India.

- Properties: Light, corrosion-resistant, good conductor of heat, malleable.

- Raw Material: Bauxite (bulky, dark reddish rock).

- Key Location Factors: Regular supply of electricity and assured source of raw material at minimum cost.

Chemical Industries

- Fast-growing and diversifying.

- Inorganic: Sulphuric acid, nitric acid, alkalies, soda ash, caustic soda.

- Organic: Petrochemicals used for synthetic fibers, rubber, plastics, drugs, and pharmaceuticals. often located near oil refineries.

Fertilizer Industry

- Centered around nitrogenous fertilizers (Urea), phosphatic fertilizers (DAP), and complex fertilizers.

- Potash is entirely imported.

- Expanded significantly after the Green Revolution.

Cement Industry

- Essential for construction (houses, factories, roads, dams).

- Raw Materials: Bulky and heavy materials like limestone, silica, and gypsum.

- Plants in Gujarat have a strategic advantage for export to Gulf countries.

Automobile Industry

- Provides vehicles for quick transport of goods and passengers.

- Liberalization and new models stimulated demand.

- Concentrated around Delhi, Gurugram, Mumbai, Pune, Chennai, etc.

Information Technology and Electronics Industry

- Covers products from transistor sets to computers and telecom equipment.

- Bengaluru: Emerged as the "Electronic Capital of India".

- Major impact on employment generation.

- Success depends on the continuing growth of hardware and software.

Industrial Pollution and Environmental Degradation

- Air Pollution: Caused by high proportions of sulphur dioxide and carbon monoxide. Smoke from factories, brick kilns, and refineries contains particulate matter. Toxic gas leaks can be hazardous.

- Water Pollution: Caused by organic and inorganic industrial wastes discharged into rivers. Major culprits include paper, chemical, textile, and tannery industries.

- Thermal Pollution: Occurs when hot water from factories and thermal plants is drained into rivers before cooling, affecting aquatic life.

- Noise Pollution: Results in irritation, anger, hearing impairment, increased heart rate, and blood pressure. Caused by industrial and construction activities.

- Land Degradation: Dumping of wastes (glass, chemicals, salts) renders soil useless and contaminates groundwater.

Control of Environmental Degradation

Sustainable development requires integrating economic growth with environmental concerns:

- Water Management: Minimizing water use by reusing and recycling in successive stages. Harvesting rainwater.

- Effluent Treatment: Treating hot water and effluents before release (Primary, Secondary, and Tertiary treatment).

- Air Pollution Control: Using smoke stacks with electrostatic precipitators, fabric filters, scrubbers, and inertial separators. Using oil or gas instead of coal to reduce smoke.

- Noise Control: Fitting generators with silencers, redesigning machinery to increase efficiency, and using noise-absorbing materials.

NTPC Example (National Thermal Power Corporation)

NTPC has ISO certification for EMS 14001 and follows a proactive approach:

- Optimum utilization of equipment and upgrading technology.

- Minimizing waste generation by maximizing ash utilization.

- Creating green belts for ecological balance.

- Ash pond management and water recycling.

- Ecological monitoring and online database management.

Quick Navigation:

| | |

1 / 1

Quick Navigation:

| | |